Revolutionizing Elastic Body Simulations: A Leap Forward in Computational Modeling

Elastic body simulation is at the forefront of modern computer graphics and engineering design, allowing us to model soft-body interactions with stunning accuracy and speed. What used to be an insurmountable challenge—calculating millions of collisions involving squishy, highly interactive materials like jelly, balloons, or even human tissue—has been transformed into a solvable problem, thanks to recent advancements. As someone with a background in both large-scale computational modeling and machine learning, I find these advancements nothing short of remarkable. They combine sophisticated programming with computational efficiency, producing results in near real-time.

In previous articles on my blog, we’ve touched upon the inner workings of artificial intelligence, such as navigating the challenges of AI and the role foundational math plays in AI models. Here, I want to focus on how elastic body simulations employ similar computational principles and leverage highly optimized algorithms to achieve breakthrough results.

What Exactly Are Elastic Body Simulations?

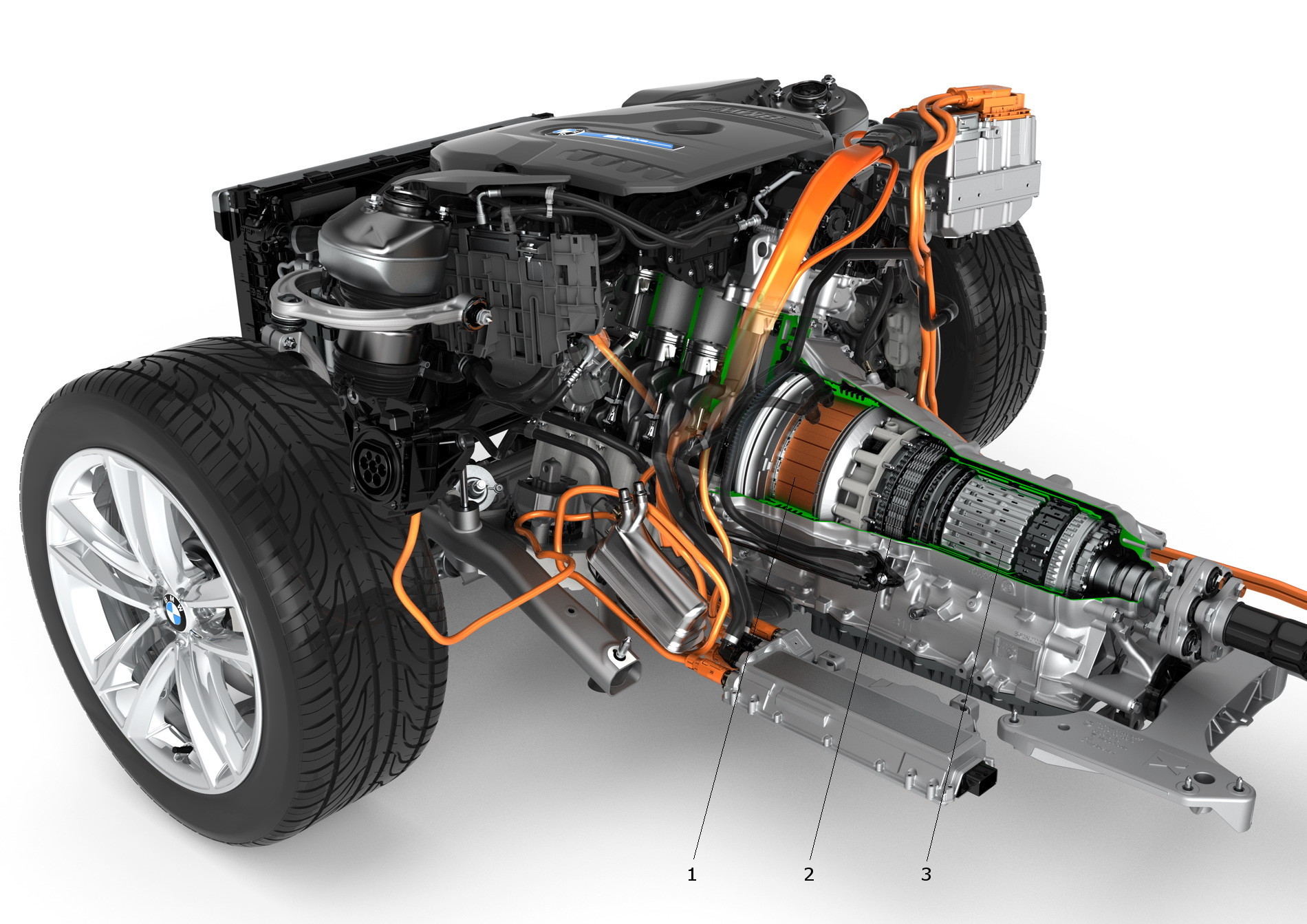

Imagine dropping a bunch of squishy balls into a container, like a teapot, and slowly filling it up. Each ball deforms slightly as it bumps against others, and the overall system must calculate millions of tiny interactions. Traditional methods would have significantly struggled with this level of complexity. But cutting-edge techniques demonstrate that it’s now possible to model these interactions, often involving millions of objects, in an incredibly efficient manner.

For instance, current simulations can model up to 50 million vertices and 150 million tetrahedra, essentially dividing the soft bodies being simulated into manageable pieces.

Image: [1, Complex soft-body simulation results]

Balancing Complexity with Efficiency

How are these results possible? The answer lies in advanced methodologies like subdivision and algorithms that solve smaller problems independently. By breaking down one large system into more granular computations, engineers and computer scientists can sidestep some of the complications associated with modeling vast systems of soft objects. One of the key techniques utilized is the Gauss-Seidel iteration, which is akin to fixing a problem one component at a time, iterating through each element in the system.

From my experience working with self-driving large-scale models during my master’s work at Harvard, solving interconnected, smaller subproblems is critical when computational resources are limited or when models need to predict responses in milliseconds. In elastic body simulation, it becomes the backbone of calculation speed and efficiency.

Real-World Implications

This extraordinary precision has implications far beyond animation. Elastic body simulations can be incorporated into various fields such as robotics, medical technology, and even automotive safety. Imagine testing an airbag design before ever needing to physically deploy one—validating how soft materials respond under various forceful impacts.

Consider the simulation of octopi with dynamically moving arms or intricate models like armadillos, which are capable of flexing and readjusting their physical structure upon compression or force. These might seem exaggerated, but their level of complexity is just a stone’s toss away from real-world applications. Anything involving soft bodies—from materials in product manufacturing to tissue modeling in biotech—can benefit from this technology. As we add more entities, computation becomes trickier, but researchers have managed to maintain model stability, showcasing just how far this work has progressed.

Video: [1, Elastic body simulation in interactive environments]

Testing the Limits

One of the most exciting aspects of these simulations is how friction coefficients and topological changes—actual tears or rips in the material—are accurately modeled. For example, a previous simulation technique involving deformable objects like armadillos might fail under the strain of torturous tests, but newer algorithms hold up. You can squash and stretch models only to have them return to their original shape, which is imperative for ensuring real-time accuracy in medical or industrial processes.

Moreover, when testing simulations with a massive weighted object like a dense cube that sits atop smaller, lighter objects, the new algorithm outperforms old techniques by correctly launching the lighter objects out of the way instead of compressing them inaccurately. What we’re witnessing is not just a minor upgrade; this is a groundbreaking leap toward hyper-efficient, hyper-accurate computational modeling.

Image: [2, Squishy object deformation under force]

The Computational Miracle: Speed and Stability

While accuracy in simulation is one marvel, speed is equally important, and this is where the new computational approaches truly shine. Early systems might have taken hours or even days to process these complex interactions. In contrast, today’s models do all this in mere seconds per frame. This is nothing short of miraculous when considering complex interactions involving millions of elements. From working with AI algorithms in the cloud to overseeing large-scale infrastructure deployments at DBGM Consulting, the need for both speed and stability has been something I continuously emphasize in client solutions.

Moreover, speed increases are not linear but logarithmic. What does this mean? A model that might have previously computed 2-3x faster can now achieve up to 100 to 1000x faster computation rates. Just imagine the expanded applications once these systems are polished further or extended beyond academic labs!

Looking Forward: What Comes Next?

The applications for these high-speed, high-accuracy simulations can extend far beyond just testing. Autonomously designing elastic body materials that respond in specific ways to forces through machine learning is no longer a future endeavor. With AI technologies like the ones I’ve worked on in cloud environments, we can integrate simulations that adapt in real-time, learning from previous deformations to offer smarter and more resilient solutions.

Image: [3, Simulation accuracy comparing different models]

The future of elastic body simulation undoubtedly appears bright—and fast! With exponential speed benefits and broader functionality, we’re witnessing yet another major stepping stone toward a future where computational models can handle increasing complexity without breaking a sweat. Truly, “What a time to be alive,” as we said in our previous article on Revolutionizing Soft Body Simulations.

Focus Keyphrase: Elastic body simulation