Why the Boeing Starliner Failed

In the summer of 2024, the world watched as Boeing’s Starliner spacecraft attempted to complete its long-awaited crewed mission to the International Space Station (ISS). However, instead of celebrating a triumph, the mission ended as a case study of persistent failures, resulting in stranded astronauts and countless delays. This blog will take a detailed look at why Boeing’s Starliner failed, examining the technical, financial, and political reasons behind its setbacks.

Historical Context and the Origins of Starliner

The Boeing Starliner, or CST-100, was Boeing’s ambitious entry into NASA’s Commercial Crew Program. The goal was to develop a crew transport vehicle to replace the retiring Space Shuttle fleet and provide a reliable means to ferry astronauts and cargo to the ISS. Boeing had a legacy of working with NASA, from the Saturn V rocket to building components of the Space Shuttle, making it a natural candidate for this high-profile project.

However, Boeing’s journey with Starliner began under a cloud of cultural change within the company. In 1997, Boeing acquired McDonnell Douglas for $14 billion, marking a pivotal shift in its corporate culture from one that prioritized engineering excellence to one increasingly driven by shareholder demands and cost-cutting. This shift is supported by multiple industry analyses and historical records, which highlight the increased emphasis on financial metrics over engineering innovation post-merger. This change ultimately impacted how projects like Starliner were managed and led to various problems in Boeing’s engineering processes, as the focus shifted away from quality and innovation towards meeting financial targets and shareholder expectations.

The acquisition fundamentally changed Boeing’s approach to project management and product development. Prior to the merger, Boeing was seen as an “engineer’s company,” where technical expertise and innovation were prioritized over profitability. However, with McDonnell Douglas’ influence, a culture of financial efficiency and shareholder returns became the primary focus. This shift in priorities laid the groundwork for the subsequent issues with the Starliner program, as engineering decisions often clashed with financial constraints and cost-cutting measures.

Technical Issues: Complex Thrusters and Software Bugs

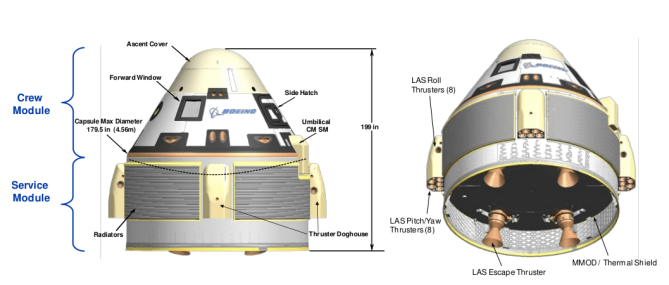

Starliner’s technical complexities were a major contributor to its failure. The spacecraft was designed with 52 individual thrusters, including:

- 28 Reaction Control System (RCS) Thrusters: Used for attitude control and orientation.

- 20 Orbital Maneuvering and Attitude Control (OMAC) Thrusters: More powerful than RCS, intended for orbital maneuvers.

- 4 RS-88 Engines: Part of the abort system to ensure crew safety during launch failures.

This level of redundancy, while crucial for safety and maneuverability, introduced additional points of failure. On its uncrewed test flight in December 2019, a software bug caused Starliner to be 11 hours off in its internal clock. As a result, the spacecraft incorrectly fired thrusters and ended up burning more fuel than planned, preventing it from reaching the ISS. According to NASA’s official report, the issue was related to incorrect mission event sequencing, which led to misfires and fuel depletion. The complexity of coordinating all 52 thrusters also meant that even minor software issues could result in significant deviations from the intended mission plan.

The thruster system, while offering flexibility and control, also significantly increased complexity. Each thruster was a potential point of failure, and this became evident throughout the test missions. The following table summarizes the types of thrusters and their respective functions:

| Thruster Type | Number of Thrusters | Function |

| Reaction Control System (RCS) | 28 | Attitude control and orientation adjustments |

| Orbital Maneuvering and Attitude Control (OMAC) | 20 | Orbital maneuvering and velocity adjustments |

| RS-88 Engines | 4 | Abort system for crew safety |

Furthermore, during a later test, 13 propulsion valves were found to be stuck due to corrosion—moisture had seeped in and reacted with the propellant, corroding the surrounding metal. This problem was traced back to faulty hardware and miscommunication between Boeing and its contractor, Aerojet Rocketdyne. The lack of clear communication channels and accountability between Boeing and its subcontractors only exacerbated these issues, leading to significant delays and cost overruns. The 2024 crewed flight saw similar issues, with multiple thrusters failing during orbital insertion and docking maneuvers.

The final mission faced yet another obstacle: a helium leak in the pressure-fed thruster system. Helium is used to pressurize the propellant tanks, and without the proper pressure, the thrusters failed to produce sufficient thrust. According to Boeing’s official investigation reports and NASA press releases, the leak was traced to a failure in maintaining adequate pressurization due to a faulty component. Boeing engineers identified that a Teflon seal was expanding under thermal stress, restricting helium flow and triggering system shutdowns. These repeated technical failures demonstrated the challenges of managing such a complex system and highlighted the consequences of Boeing’s cost-cutting culture.

The table below shows the frequency and type of failures experienced during different test flights:

| Test Flight | Thruster Issue Type | Description |

| December 2019 | Software Bug | Incorrect timing leading to off-course orbit |

| 2021 Test Flight | Valve Corrosion | 13 propulsion valves stuck due to corrosion |

| June 2024 Mission | Helium Leak | Teflon seal expansion restricted helium flow |

The high level of redundancy intended for safety instead contributed to cascading failures as each thruster, valve, or seal became another potential point of malfunction. The combination of software bugs, hardware corrosion, and system leaks highlighted a pervasive lack of integration between design, engineering, and testing phases. This fragmented approach ultimately led to a series of highly publicized setbacks that questioned Boeing’s ability to meet the technical requirements for human spaceflight.

Financial Challenges: Fixed-Price Contracts and Cost-Cutting Culture

From a financial perspective, Boeing’s fixed-price contract with NASA added another layer of difficulty. Unlike the “cost-plus” contracts Boeing was used to, this meant they had to absorb any additional costs due to delays or technical problems, reducing their potential profit margin. According to NASA’s contract details and Boeing’s financial reports, the shift to a fixed-price contract model required Boeing to be more efficient and manage costs strictly, which was a significant adjustment from the more flexible cost-plus arrangements they were accustomed to. The culture of cost-cutting—originating from McDonnell Douglas’s influence—meant that critical engineering considerations were often sacrificed in favor of reducing expenses.

The initial funding that Boeing received from NASA in 2010 under the Commercial Crew Development program was $18 million. Boeing was optimistic and initially projected an operational Starliner by 2015. However, numerous delays and a total of $4.2 billion in funding later, Boeing is still struggling to meet contractual requirements. Comparatively, SpaceX, which received a $2.6 billion contract, successfully launched its Crew Dragon in 2020, fulfilling its commitments at a lower cost and in a shorter timeframe.

Below is a comparison of the financial allocations between Boeing and SpaceX:

| Company | Initial Funding (2010) | Contract Value (2014) | Achievements |

| Boeing | $18 million | $4.2 billion | Partial successes, repeated delays, no successful crewed flight |

| SpaceX | N/A | $2.6 billion | Successful uncrewed and crewed flights, operational missions to ISS |

The financial losses for Boeing are significant, and given that the ISS is scheduled to be deorbited by the end of the decade, the window for Boeing to turn a profit or even break even is closing rapidly. The fixed-price model not only strained Boeing financially but also highlighted inefficiencies within the organization. Cost overruns became frequent, and the inability to manage expenditures without additional funding from NASA further tarnished Boeing’s reputation as a reliable aerospace contractor.

Boeing’s financial struggles were compounded by the broader company issues, particularly within its commercial aviation division. The development of the 737 MAX and its subsequent grounding due to safety issues drew financial and management resources away from the Starliner program. The shifting of priorities to mitigate losses in the aviation sector meant that Starliner was often placed on the backburner, leading to a series of cascading delays.

Political Factors: Boeing’s Lobbying and Influence

Politics played a crucial role in Boeing’s selection and continued funding. As one of the largest aerospace contractors in the U.S., Boeing has deep political connections and a significant lobbying presence in Washington, D.C. Boeing successfully lobbied for a sole-source contract with NASA, which was initially intended to guarantee full funding for Starliner. However, internal opposition at NASA, particularly from figures like William H. Gerstenmaier, led to the inclusion of SpaceX as a competitor to prevent a single point of failure.

While this decision likely saved NASA from relying solely on Boeing, it also highlighted stark differences in corporate culture. NASA astronauts who worked with both Boeing and SpaceX reported that Boeing’s engineers were often dismissive of feedback, unlike their counterparts at SpaceX who were receptive and collaborative. This claim is supported by statements from astronauts such as Doug Hurley and Bob Behnken, who have publicly discussed their experiences working with both teams. This difference in approach led to a lack of trust, and ultimately some astronauts outright refused to fly on Starliner due to safety concerns.

Boeing’s political influence also played a part in securing continued funding despite setbacks. The company’s lobbying efforts ensured that the program was extended multiple times, even when it failed to meet initial targets. This reliance on political clout rather than performance further eroded trust in Boeing’s ability to deliver. The contrast with SpaceX was stark—where SpaceX’s open engineering culture and rapid iteration led to success, Boeing’s bureaucratic processes and emphasis on lobbying seemed to hinder progress.

The Road Ahead for Boeing and Starliner

In August 2024, after multiple setbacks, Boeing discovered a root cause behind some of the thruster failures: a faulty Teflon seal. According to Boeing’s official investigation reports, the Teflon seal expanded under thermal stress, which led to helium flow issues. Despite this, the future of Starliner remains uncertain. NASA has mandated that Starliner’s next test flight must be uncrewed, as they cannot risk human lives until these issues are fully understood and resolved. Meanwhile, SpaceX continues to provide crew transport services, and its reliability record stands in stark contrast to Boeing’s struggles.

| Flight Type | Boeing Starliner | SpaceX Crew Dragon |

| Uncrewed Test Flights | 2 Failed | 2 Successful |

| Crewed Test Flights | 0 Successful | 1 Successful |

| Operational Flights | 0 | 12 |

The future for Starliner hinges on Boeing’s ability to address the myriad technical problems while navigating the political and financial landscape. With the ISS nearing the end of its operational life, the window of opportunity for Starliner is shrinking. NASA’s patience is also wearing thin, as alternative options such as SpaceX and upcoming commercial ventures continue to demonstrate more reliable performance. Boeing faces a critical decision—either push forward, investing even more resources into Starliner, or cut their losses and refocus on other aerospace initiatives.

Podcast

Using NotebookLM, I turned this blog post into a Podcast.

Conclusion: Lessons from the Starliner Program

The Boeing Starliner saga offers critical lessons about space exploration and corporate culture. The technical challenges—such as malfunctioning thrusters, software bugs, and valve corrosion—demonstrate the importance of meticulous engineering and redundancy, but they also expose Boeing’s struggle with quality control and adaptation to a fixed-price contract environment. The influence of McDonnell Douglas’ cost-cutting culture eroded Boeing’s engineering excellence, contributing to repeated failures.

Financially, Boeing’s inability to adapt to a different funding model left them vulnerable to escalating costs and diminishing returns. Politically, while Boeing leveraged its influence to secure favorable contracts, it ultimately faced increased scrutiny as repeated delays and failures jeopardized NASA’s timeline. The Starliner program serves as a cautionary tale for what happens when financial priorities overshadow engineering innovation and safety.

As the future of the ISS draws closer to its conclusion, Boeing must decide whether to continue pursuing Starliner’s success or cut their losses—both financially and reputationally. The story of Starliner also raises broader questions about the future of human spaceflight and the role of legacy aerospace companies in an era increasingly dominated by new players like SpaceX.

References

- NASA Archives and Technical Documentation.

- Public Records on NASA Funding Allocations.

- Boeing Official Investigation Reports.

Leave a Reply

Want to join the discussion?Feel free to contribute!